Brake Systems

If I want to stop a running vehicle, what can I do ?

The easiest way is cutting power flow from engine to driving wheels, then the vehicle will surely stop in a while, not so effective and quick enough as I want. Therefore, the quickest way to stop a running vehicle is to grab wheel not to be able to turn and let the road surface grip the tire surface, then we can reduce the speed of the running vehicle very effectively. But it is not easy to overcome the power from engine only with our muscle power, almost impossible, we need a special mechanical and hydraulic arrangement to be able to support our muscle power to stop the rotating wheel. This is called as a brake system.

Brake Functions

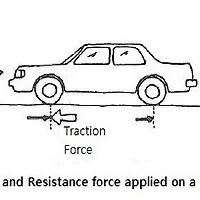

When brake applied, most important factor of brake function is friction, specially the friction force between road surface and tire. During driving, the tire surface of driving wheels are moved forward by reaction force of road surface, and during braking the tire surfaces are griped against road. To stop the vehicle, the kinetic energy of moving vehicle should be converted into other types of energy, in this case, heat and dissipated. Therefore the material of brake disc in caliper assembly, brake pad, brake drum and brake shoe should be able to resister the generated heat.

Master Cylinder

The brake power boosting device is composed of two parts, one is the hydraulic device which uses the Pascal principle to multiply driver’s muscle power and the other one is the vacuum device which uses the pressure difference between atmosphere and intake manifold. When drivers push the brake pedal with their leg muscle power, this force are transferred to brake booster (so-called “Hydro-Vac”). Inside booster, there is a master cylinder which boosts the mechanically applied power into multi-times stronger hydraulic power by using different size of valves. Furthermore, this boosting is supported by vacuum of intake manifold by connecting the low pressure chamber of the booster to the intake manifold which normally stays in vacuum status during idle phase (when driver actuate brake pedal, normally the acceleration pedal is released, therefore, engine goes to idle status).

Wheel Cylinder

In the wheel side, there are brake force actuating devices, such as, brake disc and caliper assembly (former times front wheel only but now most of passenger cars take disc type brake for front and rear wheels) or brake drum and shoe. In the wheel there is also a cylinder like master cylinder, but with a bigger diameter and section area. Because the same pressure applied in the hydraulic circuit of a brake system, the brake forces are simply proportionally increased based on the ration of sectional area of the two cylinders – master and wheel cylinder.

Because of this a little complicated system which includes hydraulic and mechanical system, the brake system has always a delay time. A driver should always think about this delay time comes from systematic reason in addition to the human’s response delay time. One more, brake system and its function is most critical system in the vehicle, and the performance is totally dependent on the friction force between road surface and tire.

Brake Fluid

Brake fluid is the blood of a brake system. The brake system can properly work only with a proper amount and characteristic of brake fluid. Brake fluid is specially blended to be able to stay functionable (keeping lubrication, transfer pressure, avoid evaporation) under extreme high (up to 250 deg. C) and low (down to -70 deg C). The most important aspect in brake fluid maintenance is to keep vapor away from the fluid. The vapor acts very negatively against the brake function.

'Automotive Technology > Body & Chassis' 카테고리의 다른 글

| Wheel Alignment (0) | 2015.03.31 |

|---|---|

| Clutch Assembly (0) | 2015.03.22 |

| ABS/TCS/VDC (0) | 2015.03.22 |

| Vehicle Performance (2) (0) | 2015.01.06 |

| Vehicle Performance (1) (0) | 2015.01.04 |